Introduction to High-pressure Water Jets

Understanding High-pressure Water Jets

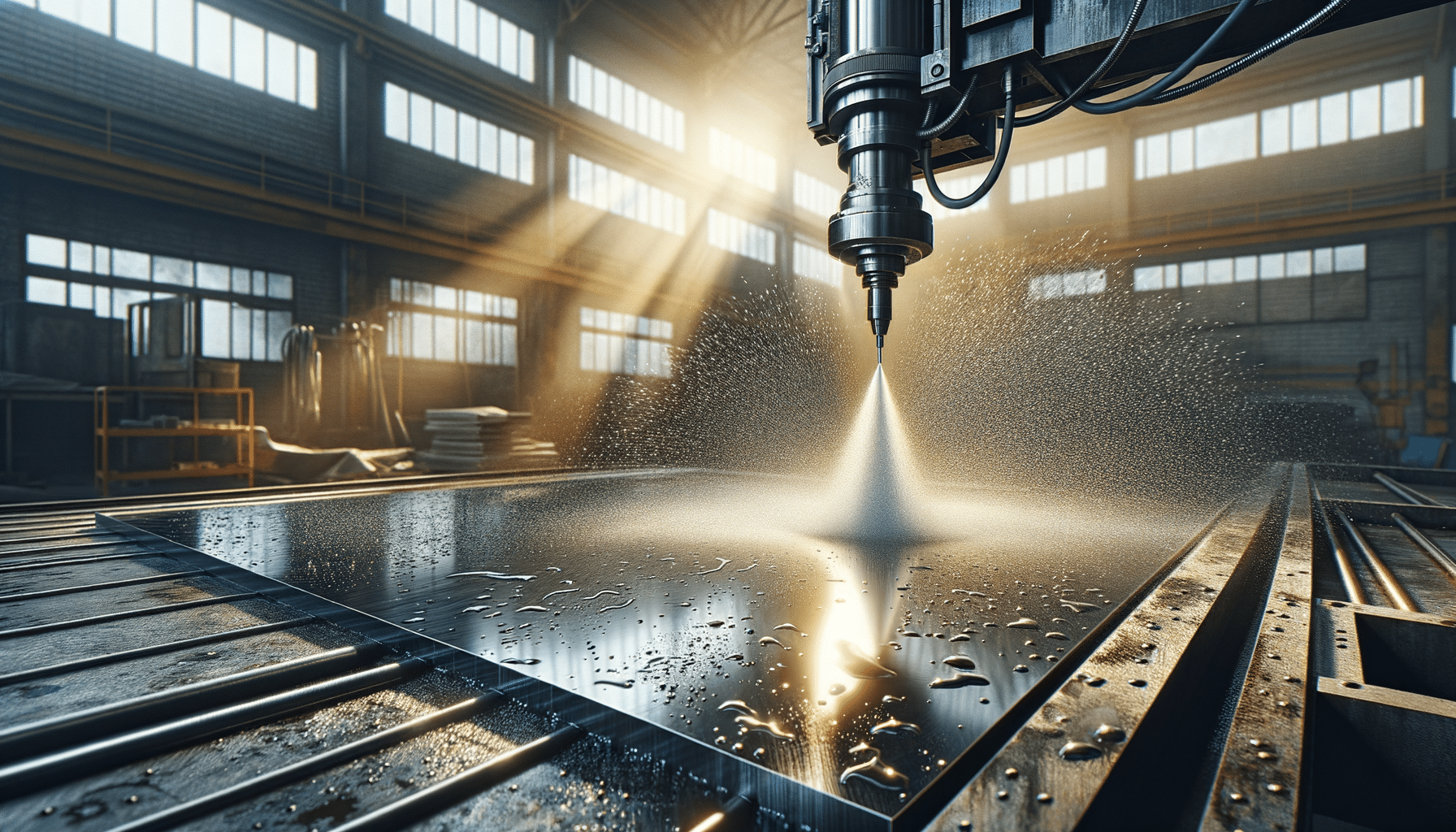

High-pressure water jets are a fascinating technology that utilizes water propelled at extremely high pressures to perform a variety of tasks. These jets are capable of cutting through hard materials, cleaning surfaces with precision, and even aiding in demolition. The versatility of high-pressure water jets makes them a valuable asset in industries ranging from construction to manufacturing. What sets these jets apart is their ability to harness the natural properties of water to achieve outcomes that were once thought impossible. By simply adjusting the pressure and the nozzle type, these jets can be tailored to suit specific tasks, offering a customized solution to complex industrial challenges.

The Science Behind High-pressure Water Jets

The science behind high-pressure water jets is grounded in fluid dynamics, where the principles of pressure, velocity, and flow are meticulously applied to achieve desired results. When water is forced through a narrow nozzle at high pressure, it transforms into a powerful jet capable of cutting through metals and other solid materials. This process is a testament to the incredible force that water can exert when harnessed correctly. The pressure applied can range from a few hundred to several thousand pounds per square inch (psi), making it adaptable for both delicate and heavy-duty operations. The technology relies on the conversion of potential energy stored in pressurized water into kinetic energy, resulting in a jet that can precisely target and manipulate materials with minimal waste and environmental impact.

Applications Across Industries

High-pressure water jets have found applications across a multitude of industries, each utilizing the technology for its unique benefits. In the construction industry, these jets are employed for cutting concrete and steel, providing a dust-free and precise alternative to traditional cutting methods. The automotive sector uses water jets for cutting materials like glass and composites, ensuring clean edges and reducing material wastage. In the realm of cleaning, high-pressure water jets are used for removing tough stains and dirt from surfaces, making them indispensable for industrial cleaning services. Additionally, the food industry leverages this technology for cutting and processing food products, maintaining hygiene and precision.

Environmental and Economic Benefits

One of the standout features of high-pressure water jets is their environmental friendliness. Unlike traditional cutting and cleaning methods that may involve harmful chemicals or produce significant waste, water jets rely solely on water, making them a green alternative. This not only reduces the environmental footprint but also minimizes the health risks associated with chemical exposure. Economically, water jets offer cost savings by reducing material waste and enhancing operational efficiency. The precision of water jets ensures minimal damage to surrounding materials, thereby reducing the need for repairs and replacements. Furthermore, their ability to perform multiple functions with a single tool reduces equipment costs, making them a cost-effective solution for businesses.

Future Prospects and Innovations

As technology continues to advance, the future of high-pressure water jets looks promising with ongoing innovations aimed at enhancing their capabilities. Researchers are exploring the integration of automation and robotics with water jet systems, allowing for greater precision and efficiency in complex operations. Advances in nozzle design are also being made to improve the cutting capabilities and reduce energy consumption. Additionally, the development of portable water jet systems is opening up new possibilities for on-site applications, particularly in remote or challenging environments. As industries continue to prioritize sustainability and efficiency, high-pressure water jets are poised to play an increasingly significant role in reshaping industrial processes.