How much does it cost to install a generator? A complete price breakdown for different types.

Overview and Outline: Why Generator Costs Vary—and What This Guide Covers

Power outages rarely send a calendar invite, yet they can upend routines, shut down home offices, and spoil groceries in a single afternoon. A generator softens that disruption, but the real question most homeowners ask is: how much does it cost to install one properly? Prices vary widely because every home, utility setup, and comfort threshold is different. This guide walks through a clear, practical breakdown so you can budget with confidence and avoid surprise costs. You’ll see what drives price, how different generator types stack up, and which line items matter most for your situation.

Here’s the outline we’ll follow so you can skim to what you need and return for details when you’re ready:

– The cost anatomy: equipment, labor, site work, transfer switches, fuel connections, permits, and regional factors

– Portable and inverter generators: purchase ranges, safe hookup options, total installation costs, and operating expenses

– Standby generators (air-cooled vs liquid-cooled): full installed price scenarios with typical line items

– Ongoing ownership: maintenance, fuel, noise, and reliability considerations that affect lifetime cost

– A decision framework to match your home, budget, and outage pattern—plus a concise conclusion

Why costs vary so much comes down to a few fundamentals. First, electrical capacity and fuel delivery are as unique as floor plans; a short, straight run from panel to pad costs less than long conduits through finished walls. Second, local codes determine pad requirements, setback distances, and which permits you need. Third, fuel availability shifts both installation and operating costs—natural gas is convenient where lines exist, propane works just about anywhere with a tank, and gasoline suits occasional portable use. Finally, your goal matters: powering a few essentials for a weekend outage is very different from running an entire home during multi-day storms.

As you read, consider your non-negotiables and nice-to-haves. For some, a quiet inverter unit for the fridge, modem, and a few lights is more than enough. Others want seamless, automatic power with a properly sized standby system that cycles weekly and self-tests. There’s no single perfect choice, only a solution that aligns with your home’s needs, your region’s weather, and your comfort with installation complexity and ongoing upkeep.

The Cost Anatomy: Equipment, Labor, Site Work, and Hidden Line Items

Generator projects combine several disciplines—electrical, gas or propane plumbing, concrete work, and permitting—so the total price is the sum of many moving parts. Understanding these buckets helps you compare quotes and identify where a budget can be trimmed without compromising safety.

– Generator unit price (typical residential ranges):

– Portable (2–7 kW, open-frame): $400–$1,200

– Inverter portable (1–7 kW, quieter/cleaner power): $600–$3,000

– Mid-size open-frame portable (8–12 kW): $900–$2,500

– PTO portable (tractor-driven, 12–25 kW, farm/rural): $1,500–$3,500 (excluding tractor)

– Standby air-cooled (10–26 kW): $2,500–$7,500

– Standby liquid-cooled (22–48 kW): $9,000–$20,000+

– Battery backup (10–20 kWh): $7,000–$15,000; (30–40 kWh): $18,000–$35,000+

– Transfer equipment and electrical gear:

– Manual transfer switch (30–50A): $300–$800

– Interlock kit: $80–$200

– Automatic transfer switch (ATS): $600–$2,500

– Inlet box, power cords, weatherproof covers: $60–$350

– Electrical labor and materials:

– Portable hookup (interlock or manual switch): $300–$1,200

– ATS integration, load management modules, subpanel work: $1,200–$3,500+

– Gas or propane work:

– Natural gas line extension/regulator: $500–$3,500 (length, trenching, meter capacity)

– Propane tank set (lease or purchase), regulator, piping: $400–$2,500 (tank size dependent)

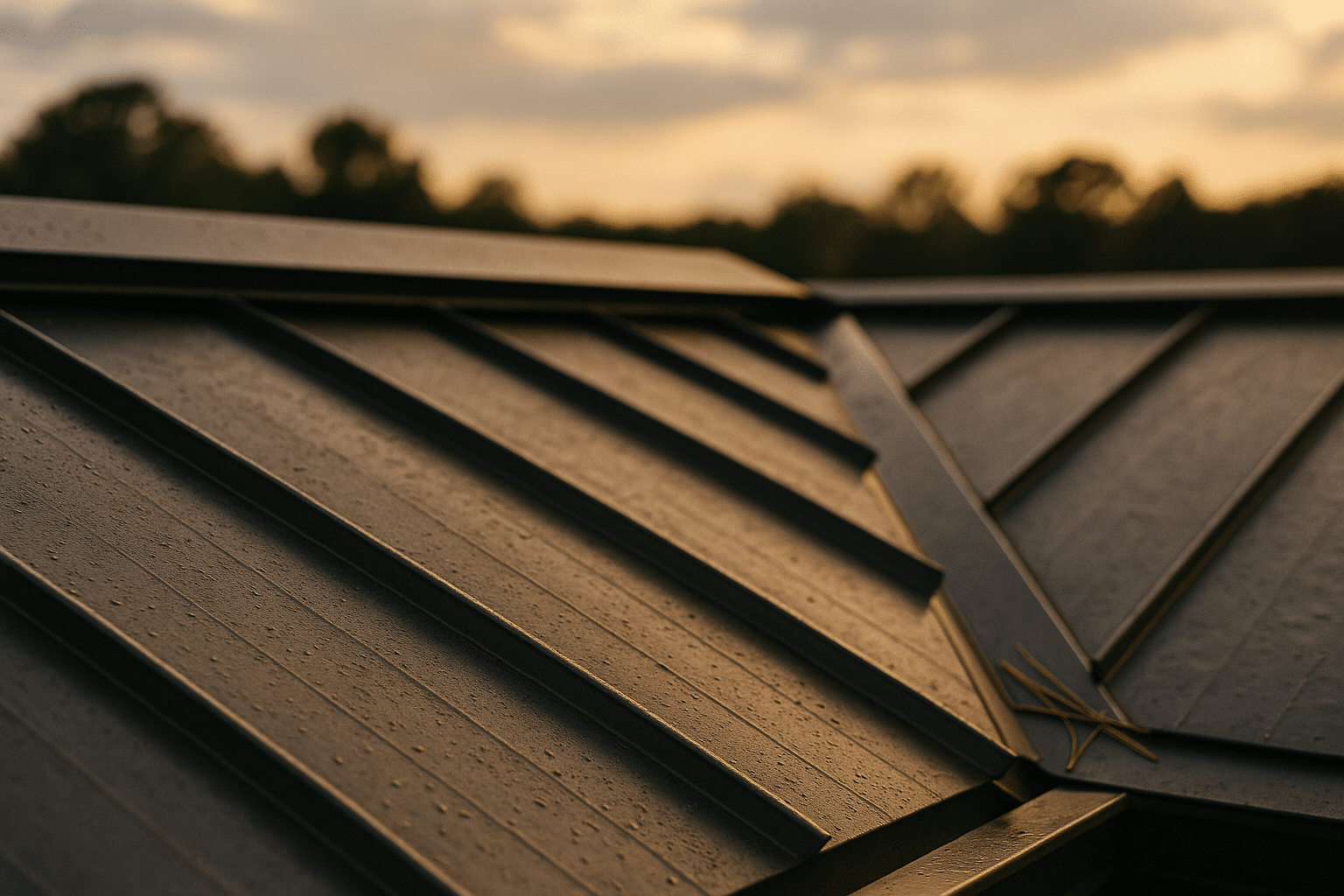

– Pad and site prep:

– Precast/composite pad: $0–$500 (often included or optional)

– Poured concrete pad: $400–$1,200

– Trenching/conduit: $15–$35 per linear foot (soil, distance, obstacles)

– Permits, inspections, and incidentals:

– Electrical/mechanical permits: $50–$600 total (jurisdiction dependent)

– Delivery/placement (small crane or boom truck): $0–$450

– Panel upgrade (if needed): $1,200–$3,500

Regional labor rates can swing totals by 10–30%. Tight urban lots may add time for routing, while older homes with crowded panels or undersized gas meters often require upgrades. A modest air-cooled standby could be a clean $7,500 install in one town and a $12,000 project in another with the same equipment because of trenching distance, meter upsizing, and permit structure. For planning, a practical rule of thumb is that “soft” costs (labor, materials, permits, and fuel connections) frequently equal or exceed the generator’s sticker price.

Budgeting tips:

– Ask for an itemized quote separating equipment, electrical labor, gas work, pad, trenching, and permits

– Verify whether load management modules are included; they can trim generator size and cost

– Confirm meter capacity and gas pressure before finalizing size; upsizing a meter late adds cost and delay

– Clarify restoration of landscaping/hardscape after trenching; this line often goes unquoted

Portable and Inverter Generators: Purchase and Installation Price Breakdown

Portable and inverter generators are popular because they offer lower upfront cost and flexibility. The key to safe use is a proper connection method that isolates your home from the utility to protect line workers and your equipment. For a small setup serving essentials—fridge, lights, modem, sump pump—a quiet inverter model paired with an interlock or manual transfer switch is a practical, budget-friendly path.

Equipment and hookup costs:

– Inverter portable (1–3 kW) for sensitive electronics: $600–$1,500

– Larger inverter (3–7 kW) for multiple circuits: $1,200–$3,000

– Open-frame portable (5–9 kW): $700–$1,800

– Interlock kit: $80–$200; manual transfer switch: $300–$800

– Inlet box and 30–50A power cord: $150–$350

– Labor (interlock or manual switch installation): $400–$1,200 depending on panel layout

Sample budget scenarios:

– Small essentials package: 2.2 kW inverter ($900) + interlock/inlet gear ($500) + labor ($500) + cords/covers ($150) ≈ $2,050 total

– Whole-room essentials with a 7.5 kW portable: generator ($1,200) + manual transfer switch ($700) + inlet/cords ($200) + labor ($900) + wheel kit/cover ($120) ≈ $3,120 total

Operating cost snapshots (actuals vary by load and altitude):

– Gasoline: a 5 kW unit at ~50% load might use ~0.6 gal/hr; at $3.50/gal ≈ $2.10/hr, roughly $0.80–$0.90 per kWh delivered

– Propane (dual-fuel models): 7.5 kW at ~50% load may consume ~0.9–1.3 gal/hr; at $2.50/gal ≈ $2.25–$3.25/hr, roughly $0.45–$0.65 per kWh

Pros:

– Lower upfront investment; scalable from camping to home essentials

– Inverter models offer quieter operation and cleaner power for electronics

– Portable format avoids permanent site work and some permits

Trade-offs:

– Manual setup during storms; you must fuel, start, and connect it safely

– Limited runtime on gasoline; fuel storage requires care and stabilizers

– Noise and exhaust constraints; not ideal for dense communities or long outages

Practical tips:

– Store enough stabilized fuel for 24–48 hours of typical use and rotate it seasonally

– Use heavy-duty, outdoor-rated cords if feeding direct loads; avoid backfeeding without proper interlock or transfer switch

– Consider a covered, ventilated parking area (never indoors) to shield from rain while maintaining safe exhaust paths

– If outages run long in your area, choose dual-fuel capability or plan for a larger propane supply

For households that face occasional, short outages, a well-planned portable setup can deliver meaningful resilience without a major construction project. The combination of safe interconnection, modest equipment, and disciplined fuel management keeps the total cost contained while protecting the essentials you care about.

Standby Generators (Air‑Cooled vs Liquid‑Cooled): Total Installed Cost Scenarios

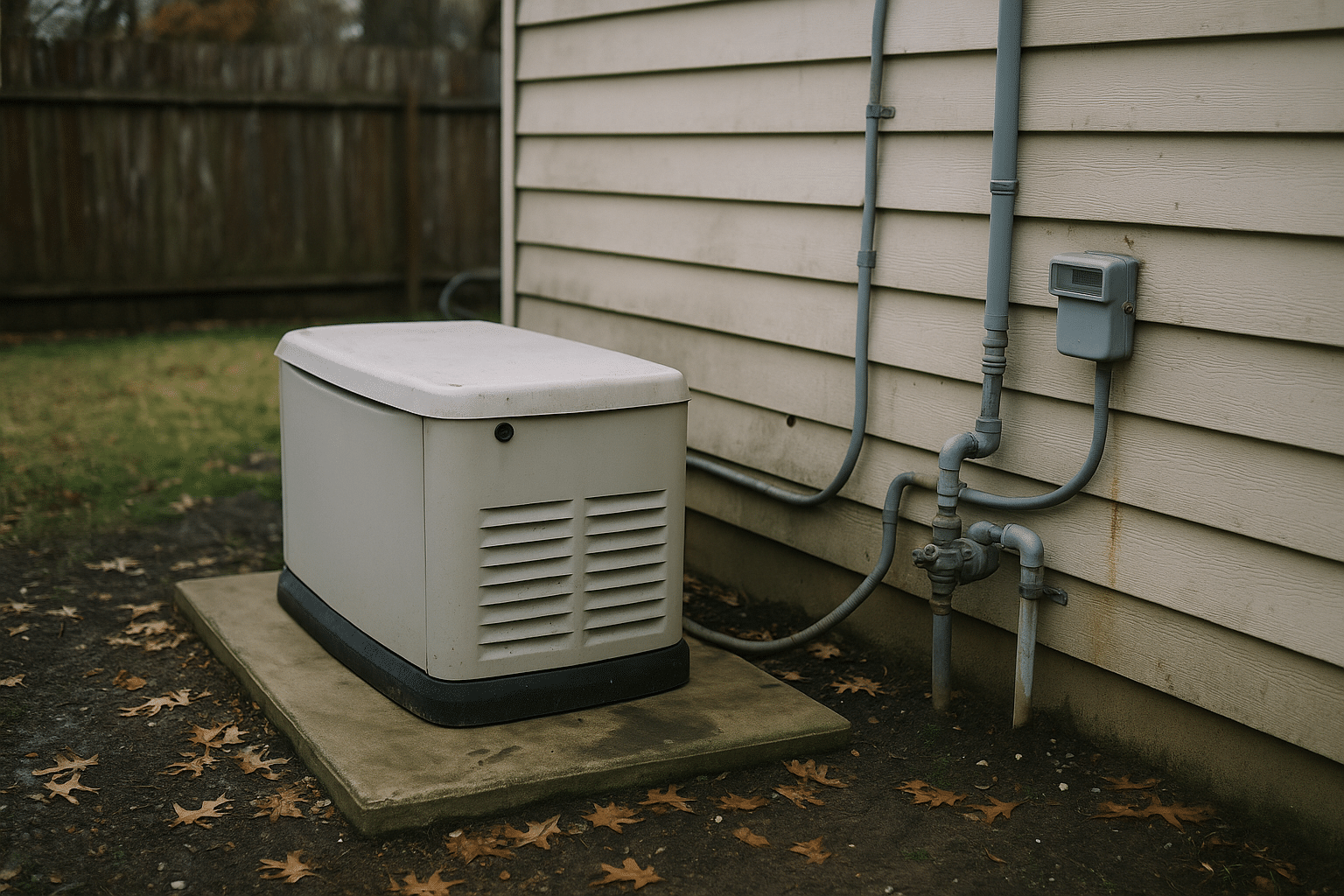

Standby systems deliver automatic power within seconds of an outage and self-test weekly, making them attractive for home offices, medical devices, or properties where pipes must stay warm. They connect via an automatic transfer switch and typically run on natural gas or propane. Pricing hinges on generator size, complexity of the gas and electrical runs, pad choice, and any upgrades to panels or meters.

Air-cooled standby (roughly 10–26 kW) typical line items:

– Generator head unit: $3,000–$6,500

– Automatic transfer switch (often bundled): $600–$1,800

– Composite or precast pad: $0–$500; poured pad: $400–$1,000

– Electrical labor/materials: $1,200–$3,000 (ATS wiring, conduit, load management modules)

– Gas work: $900–$2,500 (line extension, regulator, meter review)

– Trenching/conduit: $300–$2,000 (distance/soil dependent)

– Permits/inspections: $100–$500

– Delivery/placement: $0–$300

Typical air-cooled totals: $6,500–$15,000 installed. A compact job with the panel and gas meter close to the pad, minimal trenching, and no meter upsizing might land near the low end. A longer run across a yard with hardscape restoration, a meter upgrade, and load management modules tends toward the higher end.

Liquid-cooled standby (about 22–48 kW and up) for larger homes or extensive loads:

– Generator head unit: $9,000–$16,000+

– ATS (200–400A, service-entrance rated options): $1,200–$2,500

– Poured concrete pad: $600–$1,200

– Electrical labor/materials: $2,500–$5,500

– Gas work (larger pipe, longer runs, meter upsizing): $2,000–$6,000

– Placement/crane: $250–$450

– Permits/inspections: $200–$600

Typical liquid-cooled totals: $18,000–$38,000+, with expansive estates or challenging sites exceeding that. While these units can handle entire homes including HVAC and cooking loads, many households can achieve similar comfort by pairing an air-cooled unit with load management to stagger heavy appliances. That approach may reduce equipment size, fuel consumption, and initial outlay while preserving day-to-day convenience.

Fuel and operating cost notes:

– Natural gas: a 20 kW unit at ~50% load can burn ~180–220 cubic feet per hour; at ~$1.20/therm (100 cf), that’s ≈ $2.16–$2.64/hr, often $0.20–$0.35 per kWh delivered

– Propane: similar capacity may draw ~2–3 gallons per hour at moderate load; at $2.30/gal, that’s ≈ $4.60–$6.90/hr

Noise and placement considerations:

– Air-cooled units generally produce ~60–70 dB at 23 feet; liquid-cooled can be similar, but consult spec sheets

– Observe setbacks from windows, doors, and vents; keep clearances for service access

– Coordinate with neighbors and HOA guidelines to avoid placement conflicts

Timeline and process:

– Site visit and sizing: 1–2 hours

– Permitting/utility coordination: 1–4 weeks depending on jurisdiction

– Installation: 1–3 days for air-cooled; 2–5 days for complex or liquid-cooled

– Final inspection and commissioning: typically within a week of install

The bottom line: standby systems command a higher initial investment but deliver automatic, whole-home convenience—an advantage that becomes compelling where outages are frequent, extended, or poorly timed for manual setup.

Permits, Maintenance, Operating Costs, and the Decision Framework (Plus Conclusion)

Any generator that connects to your home’s wiring will require at least an electrical permit and inspection; gas work triggers mechanical permitting as well. Local codes govern setbacks, noise, and clearances from openings and ignition sources. Expect inspectors to verify the transfer method (manual or automatic), grounding, conductor sizing, overcurrent protection, and labeling. For propane, tank placement and anchoring rules apply, and some regions require additional seismic restraints or wind considerations.

Maintenance costs and routines:

– Portable units: change oil after break-in and every 50–100 hours; spark plug and air filter per schedule; budget $30–$80 per service if DIY, $100–$200 with a shop

– Air-cooled standby: annual service typically $150–$400 (oil, filter, plug, inspection); battery replacement every 3–5 years is often $80–$200

– Liquid-cooled standby: service intervals can be longer but parts and fluids cost more; plan $250–$600 annually

– Exercise runs: most standby units self-test weekly; ensure your fuel supply and ventilation are adequate

Fuel planning and safety:

– Gasoline: store safely in approved containers away from living spaces; rotate every 3–6 months or use stabilizer

– Propane: size tanks (120–500 gallons common) for expected runtime; deliveries may delay during storms

– Natural gas: reliable for long runs if line pressure and meter capacity meet the generator’s requirement

Insurance and warranties: some insurers ask about permanent generators and fuel storage; a quick call can clarify whether any endorsements are needed. Warranties vary by manufacturer and usage hours; keep records of all services to maintain coverage. If financing the project, factor in interest costs when comparing portable versus standby over a five- to ten-year horizon.

Decision framework to right-size your spend:

– Outage profile: frequency, typical duration, and seasonality in your area

– Critical loads: refrigeration, sump, furnace blower, modem, medical devices, and preferred lighting

– Comfort targets: select-circuit coverage versus whole-home convenience

– Fuel availability: natural gas access, propane delivery reliability, or willingness to manage gasoline

– Site constraints: distance to panel and meter, trenching obstacles, HOA rules, and noise limits

– Budget bands: portable ($1,000–$3,500 installed for common setups), air-cooled standby ($6,500–$15,000), liquid-cooled ($18,000–$38,000+)

Conclusion: If your outages are brief and infrequent, a carefully installed portable or inverter system offers strong value with minimal construction. If work-from-home uptime, medical needs, or frequent storms raise the stakes, an air-cooled standby with load management strikes a thoughtful balance of cost and convenience. Larger homes or estates with complex loads may justify liquid-cooled systems for seamless coverage. Whichever path you choose, insist on safe interconnection, clear permits, and a realistic fuel plan—because the goal isn’t just buying a generator, it’s buying dependable calm when the lights go out.