Fiberglass Grilles: A Comprehensive Guide

Why Fiberglass Grilles Matter and What This Guide Covers

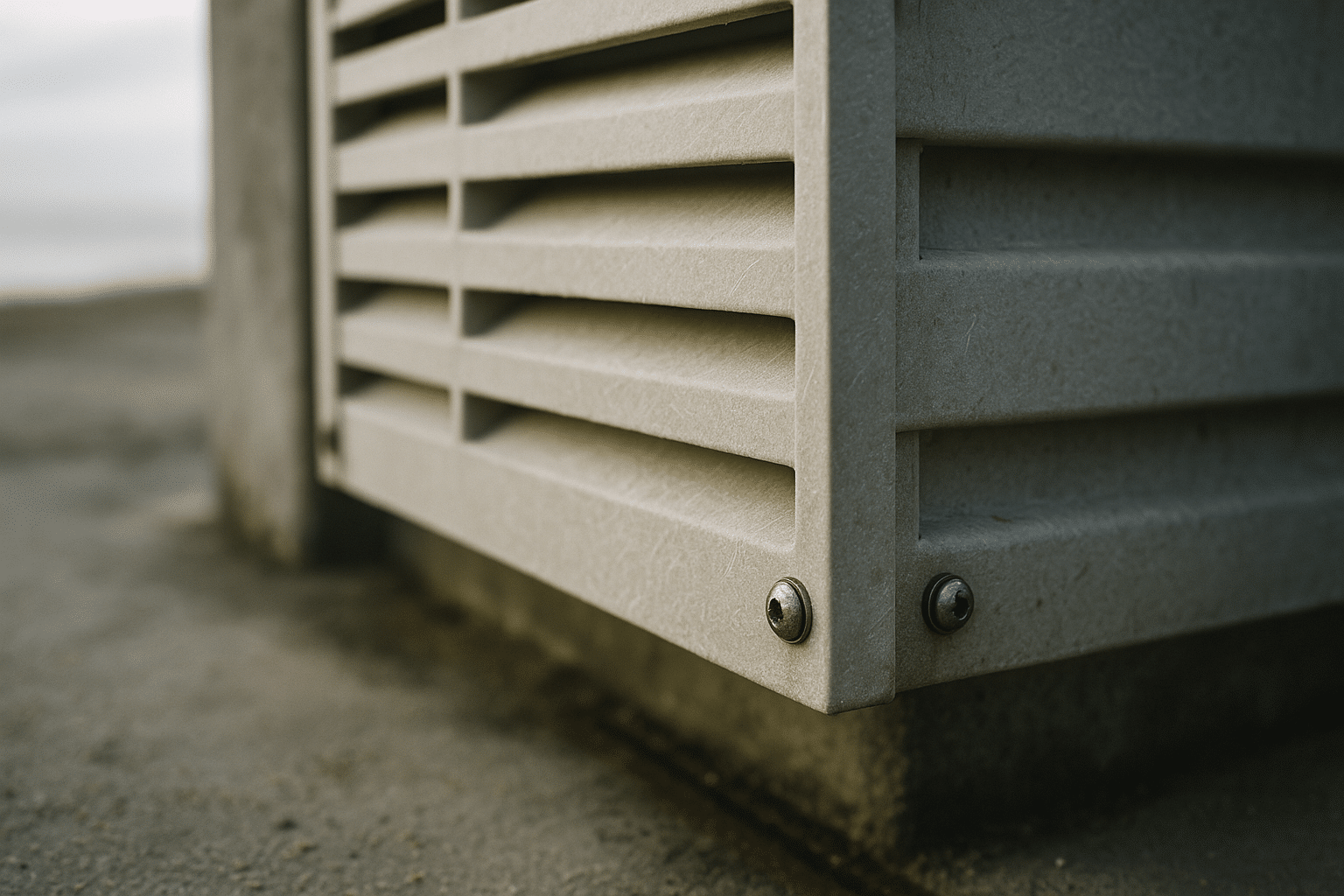

Fiberglass grilles, often categorized within fiber-reinforced polymer (FRP) components, are increasingly visible across building facades, mechanical rooms, coastal structures, and industrial walkways. They sit at the intersection of durability, low maintenance, and neutral aesthetics, offering a compelling alternative to painted metal or wood where moisture, salt, or chemicals would quickly take a toll. Because fiberglass combines glass fibers with a polymer resin, it brings a high strength-to-weight ratio, corrosion resistance, and electrical non-conductivity in one package. For facility managers, architects, HVAC professionals, and DIY renovators, these characteristics translate into fewer replacements, safer handling on site, and steady performance in harsh environments.

To set expectations, this guide uses plain language and practical benchmarks wherever possible. You will find references to commonly used performance tests (for example, flexural properties measured per standard protocols), temperature ranges, and rough cost drivers. While exact ratings depend on product and project specifics, the patterns are consistent enough to inform confident decisions. Think of this as your working field note: informative, decision-focused, and grounded in real-world constraints such as airflow targets, load limits, and maintenance budgets.

Here is a quick outline of what follows so you can skim to what you need first:

– Materials and manufacturing: fibers, resins, and how processes like pultrusion shape performance.

– Performance and comparisons: strength, corrosion, thermal behavior, fire, acoustics, and lifecycle cost.

– Applications and selection: where fiberglass grilles excel, how to size and specify, and code considerations.

– Installation and maintenance: fasteners, cutting, expansion gaps, cleaning, and repair options.

– Conclusion: a concise checklist tailored to common buyer profiles.

Why do fiberglass grilles matter now? Several shifts are converging: tightening corrosion-control requirements in coastal and industrial zones; growing emphasis on worker safety around electrically non-conductive components; pressure to reduce repainting cycles; and attention to whole-life environmental impact. In parallel, fabrication methods have matured, broadening design options from simple bars to refined aero profiles that reduce pressure drop. In many projects, the question isn’t whether fiberglass can perform, but whether its specific balance of properties aligns with your target loads, airflow or water throughput, and maintenance plan. By the end of this guide, you’ll have a structured way to answer that question with clarity and confidence.

Materials and Manufacturing: Inside a Fiberglass Grille

Every fiberglass grille starts with two pillars: reinforcement and resin. The reinforcement is commonly E-glass fibers arranged as rovings, mats, or woven fabrics. Fiber volume fraction typically lands between 40% and 60%, a range that offers a useful balance between stiffness and impact tolerance. The resin matrix binds these fibers and protects them from moisture and chemicals; widely used systems include unsaturated polyester (cost-effective general use), vinyl ester (enhanced corrosion resistance), and epoxy (noted for adhesion and fatigue performance). Additives further tune behavior: UV stabilizers reduce chalking, fire-retardant fillers help achieve low flame-spread indices, and pigments provide through-color that tolerates scratches better than surface-only paint.

How those ingredients come together determines the grille’s mechanical and dimensional traits. Pultrusion—continuous pulling of fiber bundles through a resin bath and heated die—creates straight, consistent profiles with tight tolerances and fiber alignment along the length, which raises axial stiffness and strength. Resin transfer molding channels resin into a closed mold containing dry fiber preforms, enabling complex shapes with good surface finish and controlled fiber wet-out. Compression molding can produce panels with embedded textures that boost slip resistance for pedestrian surfaces. Open-mold layup remains viable for custom geometries or short runs, though it demands careful process control to achieve uniform laminate quality.

Design details matter as much as the process. Ribbing, web thickness, and joint geometry govern how a grille handles bending and impact. Edge sealing slows moisture ingress at cut ends, sustaining long-term properties. Typical density for a fiberglass laminate is about 1.6 to 2.0 g/cm³—roughly one quarter the density of carbon steel—so handling and installation are easier, often without heavy equipment. Thermal expansion is generally in the range of 10 to 30 microstrain per degree Celsius along the primary fiber direction, higher across fibers, and lower than many commodity plastics; designers accommodate this with small perimeter gaps and slotted fastener holes. Surface options include smooth gelcoat, micro-textured profiles for improved traction, and grit-embedded top layers (commonly aluminum oxide) for wet environments.

If the application involves sunlight, flame exposure, or aggressive chemicals, material choices tighten. UV inhibitors and pigmented resins resist fading and chalking. For fire performance, halogen-free systems are available that help meet stringent interior flame spread and smoke development targets. In chemically rich sites—think wastewater treatment or pulp-and-paper—vinyl ester matrices are widely selected for their resistance to acids and chlorides. These knobs—fiber architecture, resin chemistry, and forming method—let specifiers tailor fiberglass grilles to specific, measurable requirements without reinventing the design each time.

Performance Benchmarks and Comparisons That Matter

Strength-to-weight is the headline. Typical fiberglass laminates used in grille profiles deliver flexural strength on the order of 200 to 350 MPa, with flexural modulus around 18 to 30 GPa, depending on fiber content and orientation, as measured by standard test methods. That stiffness is below aluminum (about 69 GPa) and well below carbon steel (about 200 GPa), but the much lower density means a given part can be lighter while still meeting deflection limits. For pedestrian or equipment-support applications, designers often check spans to criteria such as L/240 or L/360 to limit bounce and visual sag. Because fiber alignment boosts directional properties, pultruded slats oriented with the load path exhibit particularly efficient performance.

Corrosion resistance is where fiberglass grilles distinguish themselves from bare or painted metal. In salt fog, acidic condensate, or chlorine-laden air, properly formulated FRP avoids the blistering and underfilm corrosion that drive repaint cycles in metals. In coastal zones, labor saved on scraping and coating can dominate lifecycle savings. In many HVAC uses, operating velocities of 2 to 4 m/s across a grille with 65% to 90% free area produce modest pressure drops—often in the 5 to 30 Pa range—especially when slats are profiled rather than flat. That difference adds up over thousands of fan hours per year.

Thermally, fiberglass is a poor conductor relative to metals: thermal conductivity typically around 0.25 to 0.35 W/m·K, compared with roughly 50 W/m·K for some steels and 205 W/m·K for common aluminums. This property curbs thermal bridging in building envelopes and makes the material more comfortable to handle in extreme temperatures. Electrical non-conductivity (with dielectric strengths on the order of 10 to 20 kV/mm for solid laminates) is valuable where workers or equipment must be insulated. Radio-frequency transparency is a quiet advantage for telecom enclosures that need protective grilles without detuning antennas.

Fire and smoke behavior depends strongly on resin selection and additives. Many interior-grade fiberglass formulations achieve a flame spread index below 25 and smoke development below 450 in standard tunnel testing, placing them among low spread options for corridors or return-air plenums when permitted by local codes. Service temperatures commonly range from -40°C up to 100–120°C for continuous exposure, with short surges tolerable if mechanical load is modest. UV exposure can cause surface chalking over years; UV-stabilized resins and pigments significantly slow this effect, and cleaning reduces the appearance of chalk if it occurs.

Against alternatives, the trade-offs are straightforward:

– Versus steel: far lighter and corrosion-resistant, but lower stiffness; often higher upfront material cost offset by reduced painting and labor.

– Versus aluminum: better corrosion resistance in chlorides and lower thermal bridging; aluminum offers higher stiffness and wider commodity availability.

– Versus wood or MDF: fiberglass resists rot, swelling, and termites; wood may win on warmth and ease of field modification but requires sealing.

The implication is practical: choose fiberglass grilles where corrosion, electrical safety, or thermal bridging are real concerns, or where installation logistics favor lighter components. Pair the material with sound design—adequate spans, appropriate coatings or pigments—and it delivers steady, predictable performance for years.

Applications, Selection Criteria, Installation, and Maintenance

Fiberglass grilles turn up in a wide set of roles. In mechanical rooms, they serve as return or exhaust coverings that resist condensation and cleaning chemicals. On building skins, they soften sun glare and add depth while avoiding thermal bridging at anchors. In coastal marinas, wastewater plants, and food-processing sites, they function as walkable covers or splash guards where corrosion would quickly pit metal. Even residential projects use them as privacy screens and intake covers that do not rust onto stucco or masonry.

Translate those roles into requirements with a simple selection checklist:

– Environment: coastal salt, acid/alkali cleaning, UV exposure, interior plenum rating needs.

– Loads: pedestrian live loads (for walkable panels), wind suction/pressure, impact from carts or debris.

– Performance: free area (often 65%–90%), target pressure drop at approach velocity, acoustic needs.

– Fire and code: flame spread/smoke indices, local mechanical and energy codes, plenum approvals where applicable.

– Geometry: span and support spacing, slat profile, bar spacing to meet safety and visual requirements.

– Durability: UV-stabilized resin, grit topcoat for wet traction, edge sealing at field cuts.

Installation is largely straightforward. Field cuts can be made with carbide or diamond blades; wear eye and respiratory protection and support the workpiece to avoid chipping. Seal cut edges with compatible resin or sealant to protect fibers from wicking. Use corrosion-resistant fasteners—stainless steel or polymer anchors—and include oversized or slotted holes to accommodate thermal movement. Where vibration is expected, add isolators between the grille and substrate. For facade or screen installations, include a small perimeter gap (often 3 to 6 mm) for expansion and drainage, and align fasteners with concealed ribs or reinforced zones to prevent localized crushing.

HVAC designers can estimate pressure drop by starting with manufacturer free-area data, then checking velocities. As a rule of thumb, keeping approach velocity near 2 to 3 m/s with at least two-thirds free area keeps resistance low for most return grilles. For walkable grilles, use deflection limits (for example, L/240) to size spans and supports. Where safety under wet conditions matters, look for grit or textured surfaces that achieve wet dynamic coefficients of friction around 0.5 to 0.7, and confirm with site testing if necessary.

Maintenance is minimal but not zero. Rinse or wipe with mild detergent and water; avoid harsh solvents that can dull the surface. Schedule annual inspections to look for:

– UV chalking or fading on sun-exposed faces.

– Impact nicks or edge damage near high-traffic areas.

– Loose fasteners or worn isolators.

If damage is shallow, sanding and a compatible resin topcoat often restore appearance and seal fibers. Deeper cracks call for section replacement, but modular systems make that swap practical without dismantling adjacent components. With these habits, fiberglass grilles deliver long, predictable service in settings that punish less durable materials.

Conclusion: A Practical Path to Smarter Grille Choices

If you manage facilities, specify envelopes, or oversee mechanical systems, fiberglass grilles offer a clear value proposition where moisture, salt, or chemicals drive premature failures in other materials. Their light weight speeds installation, electrical non-conductivity supports safer work zones, and corrosion resistance shrinks repaint cycles. The trade-offs—lower stiffness than metals and a need for UV-aware formulations—are manageable with good design and honest site assessments.

Use this simple end-of-project checklist:

– Confirm environment, loads, and code requirements before finalizing geometry.

– Choose resin and additives to match UV, fire, and chemical needs.

– Allow for expansion in mounting details and seal field-cut edges.

– Verify airflow or drainage targets with free area and approach velocity.

– Plan light, regular cleaning and annual inspections.

For architects, that recipe yields durable screens and louvers that hold their color and line. For HVAC teams, it means predictable pressure drops and fewer corrosion surprises in damp plenums. For maintenance crews, it’s fewer hours on ladders with scrapers and brushes. When the operating context rewards corrosion resistance, electrical safety, and low upkeep, fiberglass grilles are a well-regarded option that pays back in service life, not just in the first delivery.