Understanding the Significance and Selection of Used Transmissions

Why Used Transmissions Matter: Cost, Sustainability, and Real-World Reliability

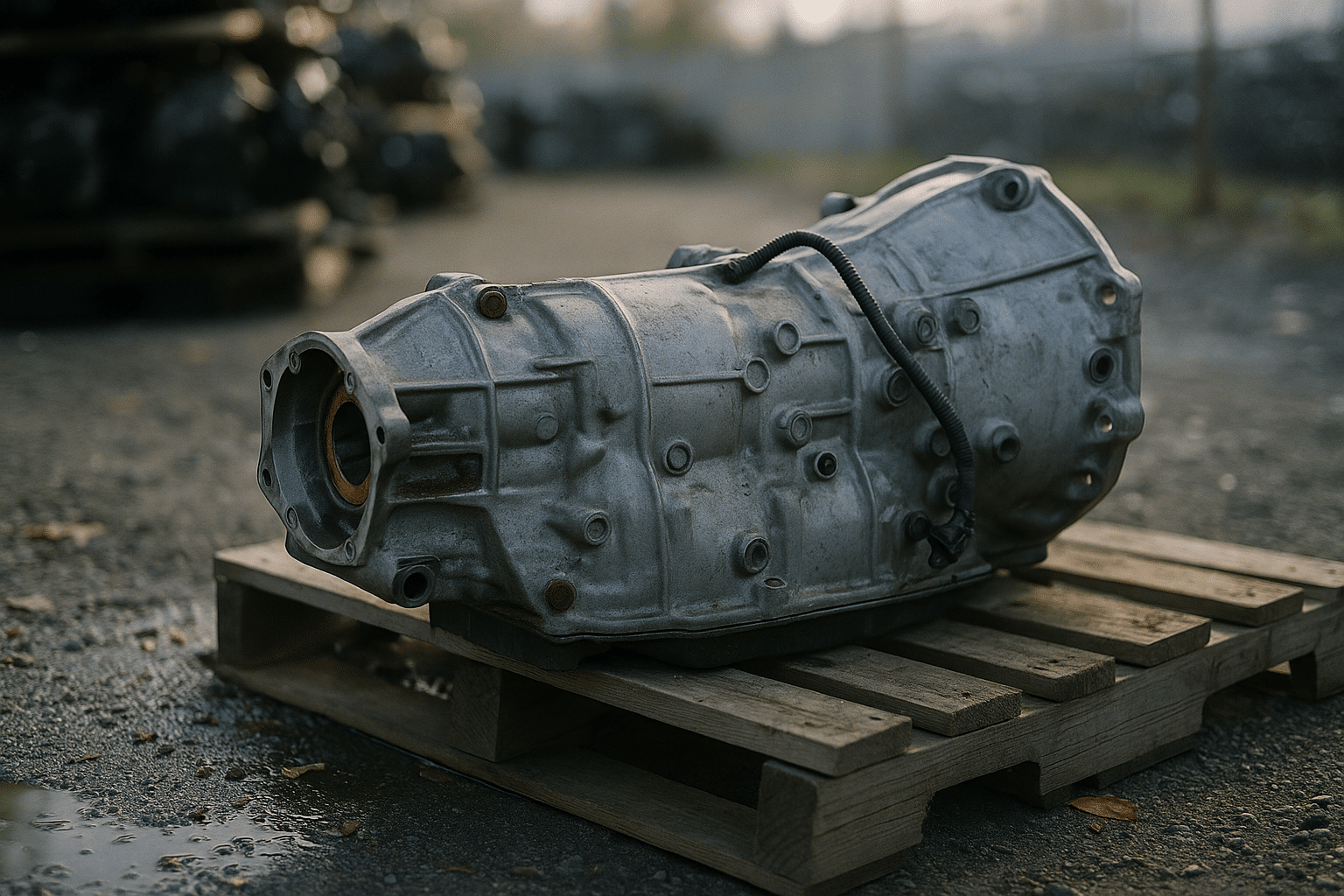

When a transmission fails, choices arrive fast and rarely at a convenient time. A new or fully remanufactured unit often commands a premium, while a used transmission can return a vehicle to service for a fraction of that outlay. For many drivers, the appeal is straightforward: meaningful savings without sacrificing everyday usability. In a market where vehicles are kept longer and budgets must handle competing priorities, understanding how to evaluate a used option is both practical and empowering.

Cost is usually the headline. Depending on type, condition, and availability, a used transmission may cost 30–60 percent less than a remanufactured unit. A typical range for many passenger vehicles might run from a few hundred dollars for a simple manual gearbox to a few thousand for complex multi-gear automatics or dual-clutch designs. Labor, fluids, and programming still apply, but the overall bill can remain manageable. At the same time, reuse carries environmental benefits: reclaiming a serviceable assembly reduces waste, lowers demand for new parts, and extends the life of the donor vehicle’s components.

Reliability is less about luck than process. A used transmission sourced with documentation, tested by the seller, and inspected with care can deliver years of service. The key is to approach the purchase with a method: identify the correct variant, verify compatibility and history, assess condition, and confirm warranty terms. Viewed this way, buying used is closer to a research project than a gamble, and the payoff is a vehicle that shifts cleanly without emptying the wallet.

To set expectations and provide a roadmap, here’s the outline this article follows:

– Why used transmissions matter: economics, sustainability, and practical reliability

– How different transmission types age and what that means for a used purchase

– Where to source a unit and how to verify history, compatibility, and documentation

– Inspection and testing checklist before payment or installation

– Pricing, warranties, and total cost of ownership, followed by a step-by-step conclusion

Think of the path ahead like tightening a row of bolts: one careful turn at a time. With clarity on the stakes and a structured approach, you can choose a used transmission that feels steady, shifts confidently, and keeps your plans moving forward.

How Transmissions Age: Manual, Automatic, CVT, and Dual-Clutch Compared

Not all transmissions wear the same way, and understanding age-related patterns helps you judge risk. Manual gearboxes are mechanically simple and often survive high mileage with minimal internal wear, provided the fluid was changed periodically and the driver treated the shifter and clutch respectfully. Common age markers include synchro wear leading to second- or third-gear crunching, input shaft seal weeping, and selector linkage play. Because the clutch is external, a used manual paired with a fresh clutch kit can feel remarkably rejuvenated.

Conventional automatics rely on hydraulic pressure, clutch packs, and a torque converter. Over time, heat and contaminated fluid degrade friction materials, and sticky valve bodies can cause delayed engagement, flares, or harsh shifts. Units that have seen frequent towing without additional cooling or extended intervals without fluid service are more vulnerable. Evidence of good care includes fluid changes at reasonable mileage, a clean pan with minimal metallic fuzz on the magnet, and crisp, predictable shift behavior in a test video or donor-vehicle demonstration.

Continuously variable transmissions operate via belts or chains and variable pulleys. They prioritize smoothness and efficiency, but belt and pulley surfaces are sensitive to heat and fluid quality. Age shows up as whining under load, shudder on takeoff, or slipping at steady throttle. For a used purchase, lower mileage paired with documented fluid service is reassuring. Look for units from vehicles that were not frequently overloaded and that show no metal glitter in the drained fluid.

Dual-clutch transmissions combine mechanical gearsets with automated clutch control. They deliver fast shifts but depend on precise control systems and healthy clutch packs. Age-related issues can include judder when starting from a stop, inconsistent engagement, or control module faults. While many used examples perform well, prioritize units with proof of proper software calibration, clean connector pins, and no history of overheating alerts.

Quick comparisons to guide expectations:

– Manual: Often resilient; watch for synchro wear, seal leaks, and bearing noise

– Automatic: Sensitive to fluid condition and heat; inspect pan debris and shift quality

– CVT: Prefer lower mileage and verified service; avoid units with whine or glittery fluid

– Dual-clutch: Check clutch wear indications and control-module health; look for smooth takeoff

Mileage is only part of the story. A carefully maintained 120,000-mile automatic may outperform a neglected 70,000-mile unit. Focus on care history, operating environment, and evidence of recent, healthy behavior. When you combine type-specific knowledge with thorough verification, a used transmission can be a pragmatic choice rather than a roll of the dice.

Sourcing and Verification: Where to Buy and What to Ask For

Finding a reliable used transmission begins with choosing the right source. Auto recyclers and dismantlers often inventory units by interchange number, gear ratio, and drivetrain configuration, making it easier to match the exact variant you need. Specialty transmission recyclers may provide additional testing, photos of the pan and magnet, and compatibility notes. Online marketplaces can broaden availability, but the burden of verification grows—insist on clear documentation and communication.

Start by defining compatibility with precision. Gather your vehicle’s model year, engine size, drivetrain layout, final-drive ratio, and any relevant production splits. Confirm the transmission code or family and whether auxiliary features—such as an external cooler or integrated control module—must match. Ask the seller to confirm the donor vehicle details, including mileage at the time of removal and the reason the vehicle was dismantled. A low-impact collision donor is often a better sign than a powertrain failure.

Documents and evidence to request:

– Written invoice with part number or interchange reference and stated mileage

– Donor VIN for verification and build-date confirmation

– Photos of the pan interior, drain plug, and magnet to assess debris

– Fluid sample photo against a white background to judge color and sheen

– Images of connectors, sensors, and mounting points to verify physical match

– Any bench-test or road-test video demonstrating engagement and all forward gears

Probe for details about handling and storage. A unit kept sealed, capped at all ports, and stored indoors away from dust and moisture is preferable. Ask whether the cooler lines were flushed and capped at removal and if the torque converter (for automatics) is included and marked to the transmission it came from. For manuals, check whether the shifter linkage and throwout bearing are included, noting that wearable clutch components are usually replaced during installation.

Verification checklist before committing funds:

– Confirm ratio and code match to avoid drivability and programming conflicts

– Check for cracks, broken ears, stripped threads, or damaged connectors in photos

– Ensure no excessive glitter in fluid; a light, silvery haze is different from visible flakes

– Review warranty terms, including length, claim steps, and exclusions for overheating or contamination

– Clarify shipping details, palletization, and liftgate needs to prevent delivery damage

Good sellers communicate clearly, provide specific images on request, and state policies without hedging. When information is vague, press for clarity or move on. A few extra messages up front can save hours in the shop and hundreds of dollars later.

Pricing, Warranties, and Total Cost of Ownership

Budgeting for a used transmission is more than comparing sticker prices. Count the full stack of costs: the unit, shipping, installation labor, fluids and filters, seals and mounts, cooler flushing, and any required programming or relearn procedures. Used manual gearboxes for common passenger vehicles can land anywhere from a couple of hundred to just under a thousand dollars, while conventional automatics often range from several hundred to a few thousand depending on gears, drivetrain, and scarcity. CVT and dual-clutch units typically price higher due to complexity and demand but can still undercut remanufactured options by a significant margin.

Labor varies widely with vehicle layout. Front-wheel-drive installations might require 5–9 hours, while rear-wheel-drive trucks or complex all-wheel-drive platforms can reach 8–12 hours or more. Shop rates differ by region, so it pays to get multiple quotes. Plan for fresh fluid and a new filter where applicable, new axle seals, and a careful cooler flush to remove old debris. For automatics, confirm whether the torque converter is included; if not, budget for a compatible unit and installation.

Warranties are a crucial part of risk management. Many recyclers offer 30–90 days as baseline coverage, with optional extensions that may add 6–12 months. Some policies cover parts only; others include limited labor reimbursement if installation is performed by a licensed shop and proper procedures—like cooler flushing and correct fluid use—are documented. Read exclusions closely: overheating, contamination, towing beyond rated limits, or tuning changes can void coverage. Keep every receipt, fluid brand and quantity notes, and pre-installation photos of the pan and magnet; they matter if a claim arises.

Consider an example to frame total cost of ownership. Suppose you secure a used automatic for $1,200, shipping adds $200, fluids and seals $150, and programming $120. Installation at $100 per hour for nine hours totals $900. The project lands near $2,570. A comparable remanufactured option might run $3,800 before the same incidentals and labor, pushing the total well beyond $4,500. The used route can save four figures while meeting daily-driving needs—provided your verification and installation checklist are airtight.

Risk controls that punch above their weight:

– Perform or require a cooler flush and install an in-line filter where appropriate

– Use the exact specified fluid and correct fill procedure; confirm temperatures during level checks

– Address engine or mount issues that could stress the replacement transmission

– Update software and perform relearn steps to align shift logic with the “new-to-you” unit

Red flags worth walking away from:

– Glittery fluid, burnt odor, or sludge in pan photos

– Cracked housings, broken mounting ears, or damaged connector pins

– Sellers who refuse to share donor details, warranty terms, or internal photos

– “As-is, no testing, no returns” on a complex automatic or CVT

Conclusion: A Step-by-Step Roadmap to Selecting a Used Transmission

Choosing a used transmission rewards planning more than luck. For budget-conscious drivers, fleet managers, and enthusiasts keeping a trusted vehicle on the road, a disciplined process transforms uncertainty into confidence. Begin with clear compatibility data: identify the exact code, ratios, and production splits your vehicle requires. Research how your target transmission type ages and which symptoms indicate healthy operation versus looming repair. Then focus on sourcing: prioritize sellers who document donor mileage, provide comprehensive photos, and state warranty terms in writing.

Work through a concise, repeatable checklist:

– Confirm part number or interchange reference, ratio match, and physical fitment points

– Review pan, magnet, and fluid images for debris and odor descriptions for overheating clues

– Verify connectors and sensors align with your harness and control module expectations

– Obtain a written warranty with clear claim steps and maintenance requirements

– Price the full job including fluids, seals, mounts, shipping, programming, and labor

Before money changes hands, decide how you will validate health upon arrival: visual inspection for cracks and thread damage, connector integrity, and torque converter condition for automatics. During installation, treat the process like a system refresh: flush or replace coolers where specified, install new seals, torque fasteners in sequence, and follow fill procedures by temperature. After startup, monitor for leaks, confirm shift behavior across all gears, and perform any relearn or adaptation steps so control logic matches the new hardware.

When viewed end-to-end, the value proposition becomes clear. A used transmission can deliver reliable service and meaningful savings while reducing waste and extending the usefulness of existing components. The difference between a headache and a success story is preparation: accurate identification, honest documentation, careful inspection, and meticulous installation. Approach the purchase with that mindset, and you’ll trade guesswork for a smooth, steady drive that feels right from the first shift to the last mile.