Exploring the Benefits and Considerations of Metal Roofing

Outline

1) Metal Roofing 101: Materials, Profiles, and Performance Fundamentals

2) Durability, Weather Resistance, and Safety

3) Energy Efficiency, Comfort, and Sustainability

4) Cost of Ownership, ROI, and Project Budgeting

5) Installation, Maintenance, and Design Considerations

Introduction

A roof does more than keep out rain; it shapes energy use, safety, maintenance effort, and resale value. That’s why metal roofing has moved from niche to mainstream in neighborhoods from hurricane coasts to snowy highlands. The appeal is practical: long service life, dependable protection, modern aesthetics, and increasing compatibility with solar. Yet every roof is a system, and metal is no exception—materials, coatings, fastening methods, and underlayments all influence performance. Read on for a balanced, data-informed view to help you choose with clarity.

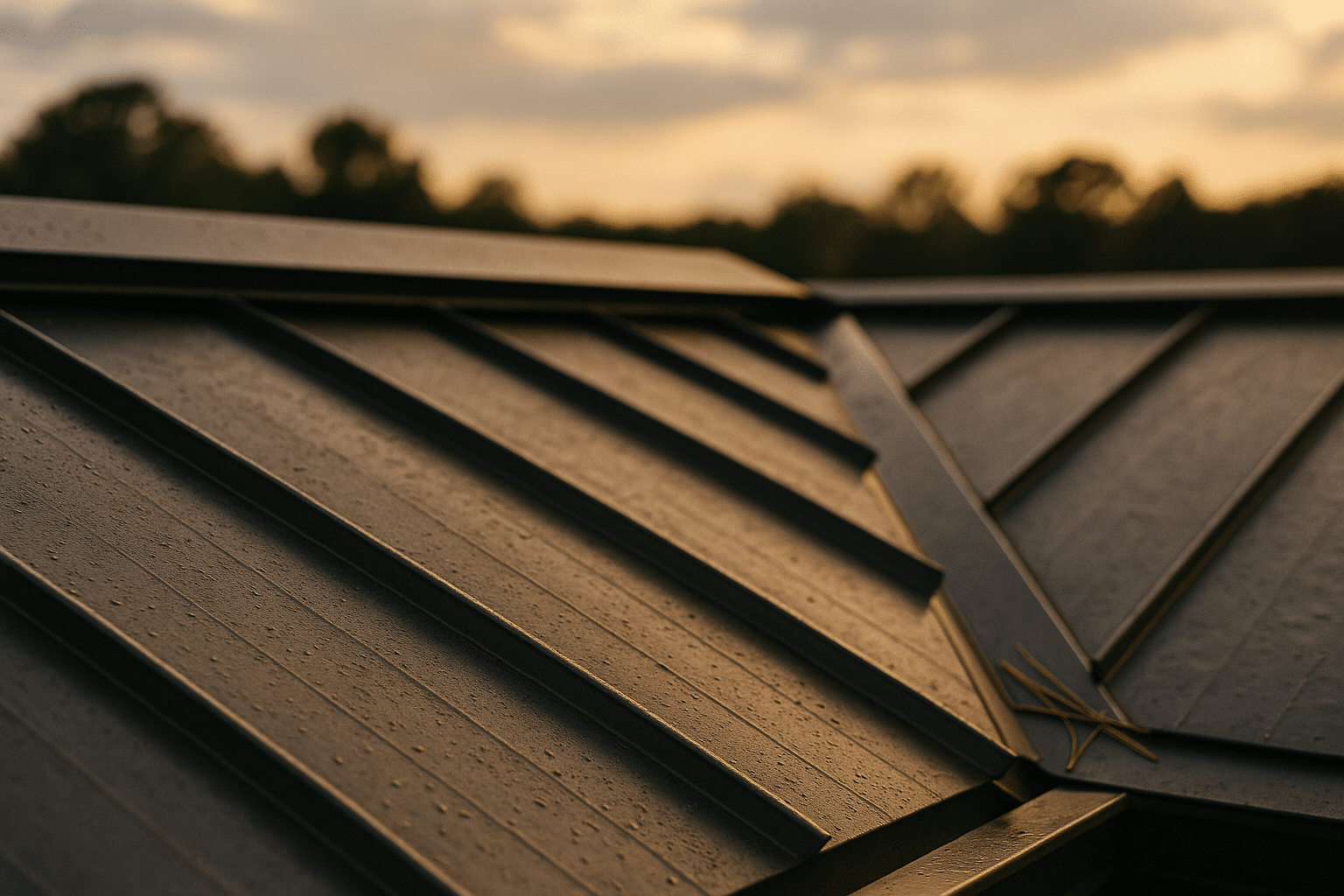

Metal Roofing 101: Materials, Profiles, and Performance Fundamentals

Metal roofing is not a single product but a family of materials and profiles tuned for different needs. The most common materials include coated steel, aluminum, zinc, and copper. Coated steel (often protected with zinc or aluminum–zinc alloys) is widely used for its strength and value. Aluminum resists corrosion in marine or coastal environments and is notably light. Zinc and copper develop protective patinas over time and offer a distinctive, evolving look alongside long service life.

Profiles influence both aesthetics and performance. Standing seam panels have concealed fasteners with raised vertical ribs; they are prized for clean lines and fewer penetrations. Corrugated and ribbed panels with exposed fasteners can be economical and are common on outbuildings and modern cabins. Metal shingles mimic the appearance of shakes, slate, or tile while keeping the benefits of metal. Thickness (gauge), panel width, and seam design affect rigidity and expansion movement under temperature swings.

Weight is a meaningful differentiator compared to other roofing types. Typical steel or aluminum systems weigh roughly 0.5–1.5 pounds per square foot, depending on profile. Asphalt shingles commonly range around 2.5–4 pounds per square foot, while slate and concrete tile can exceed 8–10 pounds per square foot. Lower weight may reduce structural demands, which can be helpful during reroof projects where additional layers or heavy finishes are impractical.

Coatings and finishes protect metal from corrosion and ultraviolet exposure. High-performance fluoropolymer paints resist chalking and fading, while silicone-modified polyester finishes offer solid durability at a lower cost. Textured or matte finishes help hide minor surface irregularities and reduce glare. Factory-applied finishes are baked on under controlled conditions, helping ensure consistent color and adhesion.

A few quick distinctions to frame your decision:

– Materials: steel for strength and value; aluminum for corrosion resistance; zinc and copper for natural patina and longevity.

– Profiles: standing seam for clean lines and fewer penetrations; exposed-fastener panels for economy; metal shingles for traditional looks.

– Finish strategy: choose high-quality coatings in climates with strong sun or salt, and consider matte or textured surfaces to soften reflections.

Taken together, these variables let you tailor the roof to climate, budget, and architectural style. The result can be contemporary or classic, utilitarian or expressive—all while delivering the core benefits of metal’s strength-to-weight advantage.

Durability, Weather Resistance, and Safety

Metal roofing has a reputation for longevity, and with good reason. Properly specified and installed, many systems deliver 40–70 years of service, outpacing common asphalt alternatives that often require replacement every 15–30 years. That additional life can be especially valuable where tear-off and landfill fees are high or where access is difficult. The durability story is not just about years; it’s about consistent performance through punishing seasons.

Fire resistance is a standout trait. Many metal roofs achieve a Class A fire rating when installed over appropriate underlayment and decking, offering strong protection against wind-blown embers in wildfire-prone regions. Metal is noncombustible, and it doesn’t ignite under typical ember exposure scenarios. On the other end of the spectrum, lightning myths persist, but metal does not “attract” strikes; it simply conducts electricity if a strike occurs. Installed over a grounded structure, metal can safely dissipate energy and is less likely to ignite than combustible coverings.

Wind and impact performance depend on panel geometry, fastening patterns, and substrate. Tested systems with interlocking seams and proper fastener spacing can withstand severe uplift forces, with ratings suitable for high-wind zones when installed to manufacturer and code requirements. Impact resistance is commonly expressed as a top-tier class under widely used industry tests, indicating strong resilience against hail compared to more brittle coverings that can crack or lose granules upon impact.

Cold-climate performance calls for smart details. Metal sheds snow efficiently, reducing heavy, lingering loads. Where rapid shedding could endanger walkways, snow guards and strategically placed diverters help control the slide. Ice-dam mitigation starts with continuous air sealing, robust insulation, and balanced ventilation to keep roof surfaces cold and prevent melt–refreeze cycles at the eaves.

Noise is often raised as a concern. In reality, modern assemblies—sheathing, underlayment, and attic insulation—dampen sound effectively. The interior experience during rain is similar to other roofs when the building has standard decking and insulation. For demanding projects, acoustic underlayments add another layer of control.

Key durability considerations to verify before signing a contract:

– Documented wind-uplift and impact ratings for the specific panel and fastening method.

– Appropriate underlayment for slope and climate, including high-temperature membranes near eaves and valleys.

– Thoughtful snow management measures where relevant, including guards and reinforced gutters.

– Clear details for transitions, penetrations, and flashings to keep water out over the long term.

Resilience is never accidental; it’s built into the system through good materials, proven patterns, and careful installation.

Energy Efficiency, Comfort, and Sustainability

Energy performance is an area where metal roofing can shine—sometimes literally. Modern “cool roof” finishes can achieve high solar reflectance and appropriate thermal emittance, reducing heat absorption under summer sun. In hot climates, studies have reported notable cooling-load reductions, especially with light-colored or reflective finishes. In mixed climates, reflective metal still helps during summer while insulation and air sealing govern winter comfort.

A metal roof functions as one layer in a broader building enclosure. Two details make or break results:

– Ventilation: balanced intake and exhaust in the attic or above-deck ventilation channels can lower roof surface temperatures and help control moisture.

– Insulation and air sealing: continuous insulation at the ceiling plane, sealed penetrations, and aligned air barriers prevent heat flow and drafts, allowing the roof’s reflectivity to deliver tangible gains.

Thermal movement is a natural characteristic of metal. Long panels expand and contract with temperature changes, so clip systems and slotted fastener holes accommodate motion without stressing seams or flashings. This is a quiet advantage for longevity: parts are designed to move so connection points don’t fatigue.

Sustainability claims deserve scrutiny, and metal offers several measurable advantages. Many products contain recycled content, and steel and aluminum are routinely recycled at end of life, diverting material from landfills. The light weight of metal can sometimes allow roof-over installations (where permitted), reducing tear-off waste. Durability reduces material turnover, which is a powerful environmental benefit rarely captured in short-term comparisons.

Metal’s smooth, inert surface also pairs well with rainwater harvesting, as it reduces debris loads and is typically compatible with filtration systems. For solar, standing seam panels are particularly convenient because panel clamps allow attachment without penetrating the roof surface, preserving the weatherproofing. The combination of a reflective, durable roof and roof-mounted solar can deliver both passive and active energy advantages.

A quick sustainability checklist:

– Choose light or reflective colors in hot regions to trim cooling energy.

– Confirm recycled content and end-of-life recyclability for your chosen alloy.

– Use above-code insulation and balanced ventilation to unlock the roof’s full comfort potential.

– Coordinate solar and snow-management plans with the roofing layout from day one.

When the enclosure works as a team—roof, insulation, ventilation, and air sealing—comfort improves, equipment runs less, and utility bills can moderate without flashy promises.

Cost of Ownership, ROI, and Project Budgeting

Upfront price is the headline, but ownership cost tells the real story. Metal roofing generally carries a higher initial installed cost than basic asphalt shingles and is often comparable to premium shingles, wood shakes, or mid-tier tiles. The spread depends on material (steel and aluminum tend to price lower than copper or zinc), profile complexity, roof geometry, and regional labor rates. Steeper slopes, multiple hips and valleys, and numerous penetrations add labor time regardless of covering.

Life-cycle economics favor long-lived systems. With service lives commonly in the 40–70-year range, a metal roof may replace two or more cycles of lower-cost coverings. Factoring in avoided tear-off, reduced disruption, and possible insurance incentives for impact- or fire-resistance, the value picture becomes clearer over a 20–30 year horizon. Maintenance demands are relatively modest—periodic inspections, fastener checks on exposed-fastener systems, cleaning of gutters, and prompt touch-up of any coatings damaged by debris.

Budget planning tips to keep surprises at bay:

– Separate material and labor in bids; panel choice, underlayment grade, and flashing complexity drive costs.

– Ask for line items on accessories: snow guards, high-temp membranes, and upgraded ventilation can be wise investments.

– Compare total cost of ownership, not just contract price; include projected maintenance and replacement timing for alternatives.

– Verify that attic insulation and ventilation upgrades are included if needed to meet current codes.

Be realistic about savings claims. Reflective finishes can reduce cooling energy in sun-exposed climates, but actual savings hinge on orientation, shading, attic configuration, and HVAC efficiency. In colder regions, energy differences may be modest, with the roof’s durability and low maintenance providing the primary financial rationale.

On resale value, buyers often respond to the combination of modern aesthetics and a long remaining service life. While market reactions vary by region, a documented, code-compliant metal roof with transferable material and finish warranties can be a strong selling point. The key is honest documentation: clear photos, permits, and maintenance records build confidence for future owners.

In short, think like an investor: a slightly higher upfront allocation can trade for decades of service, fewer tear-offs, and steadier maintenance—attributes that matter whether you plan to stay put or eventually sell.

Installation, Maintenance, and Design Considerations

Metal roofing rewards precision. The substrate should be clean, flat, and well-fastened, with damaged decking replaced before underlayment goes down. Underlayment choices include synthetic felts for standard slopes and self-adhered membranes in valleys, at eaves, and around penetrations, especially in snow or high-heat zones. Minimum roof slope varies by profile; standing seam often works well on low-slope areas within specified limits, while exposed-fastener panels typically need steeper pitches to shed water reliably.

Fastening strategy is fundamental. Concealed-fastener systems use clips that allow thermal movement; exposed-fastener panels rely on gasketed screws through the panel. Both can perform well when installed correctly, but exposed-fastener roofs require periodic screw inspection and replacement because gaskets age. Flashings—at chimneys, skylights, walls, and vents—must be detailed to move with the roof and divert water, not trap it. Sealants are a backstop, not a primary defense; good metalwork leads the water away.

Material compatibility prevents premature corrosion. Avoid direct contact between dissimilar metals known to create galvanic reactions, and separate metal from treated lumber with appropriate barriers. In coastal environments, consider corrosion-resistant alloys and fasteners, and rinse salt spray from roofs that receive heavy coastal exposure. Gutters and downspouts should be sized for local rainfall intensity and securely anchored to handle snow and ice where applicable.

Safe walking and maintenance are straightforward with a plan. Inspect twice a year and after major storms. Clear branches and debris, check for displaced fasteners, and touch up finish damage promptly to prevent corrosion starting at scratches. Keep valleys and gutters free-flowing; standing organic matter traps moisture against coatings. Where snow loads are significant, coordinate snow guards with rafter lines and avoid placing them solely over weak sheathing areas.

Design integration elevates the result from functional to exceptional:

– Align panel ribs with window and door rhythms for a cohesive facade.

– Use color thoughtfully; lighter tones reflect more sun and can visually lighten a massy roof.

– Plan solar attachments around panel seams to minimize penetrations and preserve aesthetics.

– Detail eave and ridge edges to manage water cleanly and to resist wind.

Finally, vet your installer. Ask for photos of similar projects, confirm training on the specific panel system, and request references that are at least two winters and summers old. A well-coordinated crew, clear scope, and documented details turn the promise of metal roofing into day-to-day reliability—quietly protecting your home through seasons, storms, and years.

Conclusion

Metal roofing offers a compelling mix of longevity, safety, and design flexibility, with credible energy and sustainability advantages when paired with solid insulation and ventilation. It is not a one-size-fits-all answer, and that’s a strength—materials, profiles, and details can be tuned to your climate, budget, and architectural goals. If you’re a homeowner planning a reroof or a builder specifying a new project, use the checklists in this guide to compare options side by side, ask pointed questions, and invest where it counts: in proven components and skilled installation.