Step-by-Step Guide: How to Succeed in a 6 Month Electrician Course and Earn Your Electrical Technician Certification

Introduction and 6-Month Game Plan Outline

Electric power is the quiet heartbeat of every modern building, and skilled technicians keep it steady. A structured six-month course can help you build the knowledge, habits, and portfolio that employers value, but success rarely happens by accident. It comes from a plan: choosing the right program, mastering safety, practicing every week, and preparing thoughtfully for the certification exam. This guide maps out a realistic timeline that fits the rhythm of a six-month term, showing how to turn lecture notes and lab hours into proven competence and exam readiness.

Before diving into wiring diagrams and test instruments, it helps to see the full path at a glance. Here is the outline we will expand into specific actions you can follow:

– Month 0–1: Pre-course preparation, core math refresh, basic tools, and safety foundations

– Months 2–3: Lab immersion, troubleshooting practice, and documentation habits

– Months 4–5: Codes, calculations, mock exams, and time management

– Month 6: Final review, test-day logistics, and transition into entry-level roles

– Ongoing: Continuing education and targeted upskilling

Why this matters now: many regions report steady demand for trained electrical workers, with consistent replacement needs as experienced technicians retire and building systems become more complex. Short-format training can help you enter the field faster, but the compressed timeline amplifies the importance of disciplined study. By the end of this article, you will know how to select learning resources, schedule practice, track your progress, and align every week of the course with a certification goal. Think of it as your personal blueprint: a clear circuit from day one to exam day, with checkpoints that prevent overload and reduce surprises.

Month 0–1: Pre-Course Prep, Foundations, and Smart Start Choices

The first month sets the tone, and the right habits here can save countless hours later. Begin by clarifying program format and expectations. Compare daytime, evening, and hybrid models by asking three questions: how much supervised lab time is guaranteed, what assessment methods are used, and how instructors support make-up work if you miss a session. If commuting is a factor, estimate weekly travel time and convert it into net study hours you can reclaim by batching errands. A small scheduling adjustment now can be the difference between consistent practice and constant catch-up.

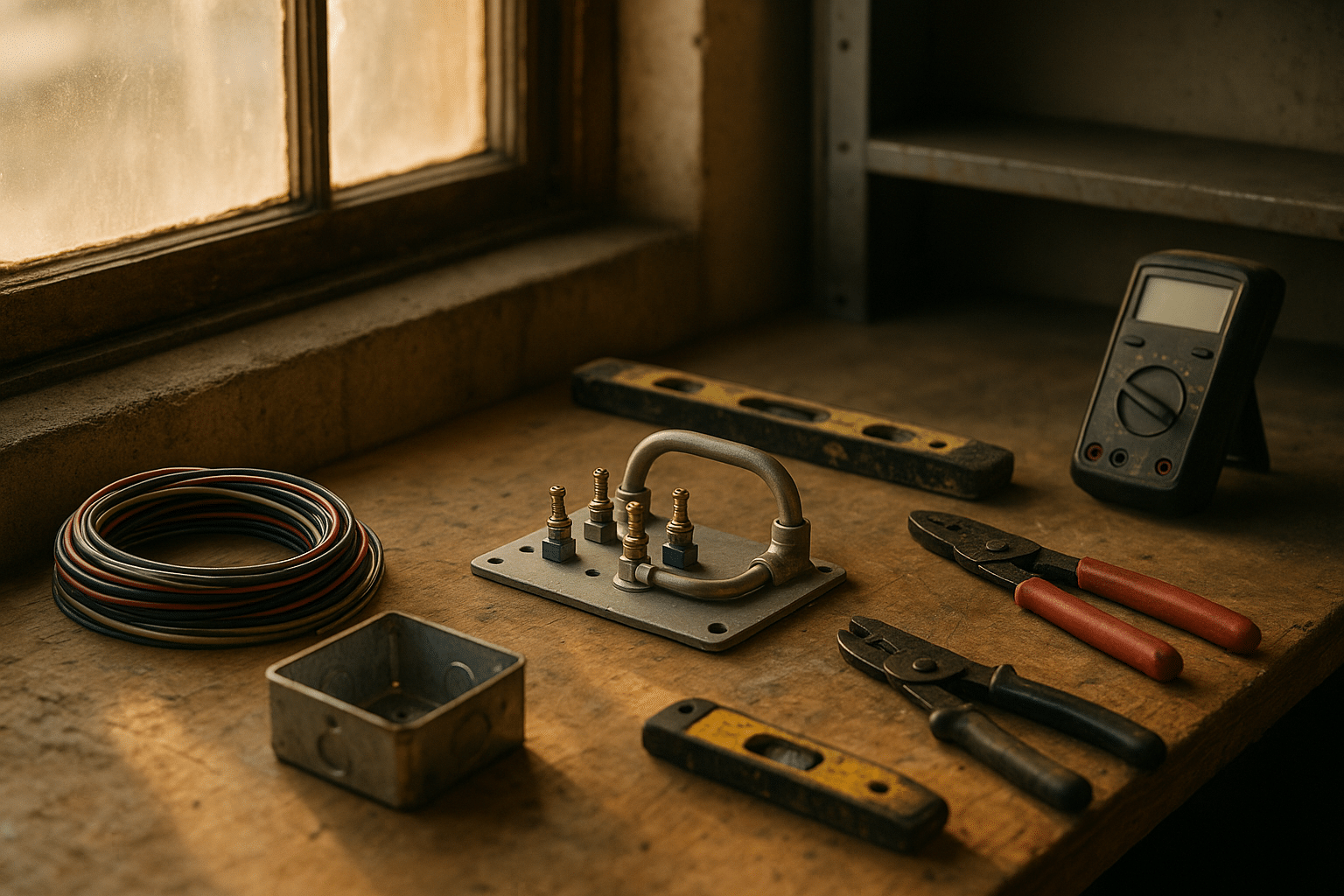

Technical foundations matter. Refresh the math you will use repeatedly: arithmetic with fractions and decimals, unit conversions, ratios, basic geometry for conduit bends, and algebra for power and current calculations. Create a single reference sheet with common formulas and conversion factors so you do not waste time re-deriving them in the lab. Next, get familiar with the tools you will handle often. Without naming brands, aim to practice with a non-contact voltage tester, a digital multimeter, wire strippers, side cutters, screwdrivers, and a tape measure. Spend an evening practicing safe meter usage on battery-powered devices and simple circuits so that your first lab day feels routine rather than risky.

Safety starts on day one and never stops. Learn the concept of de-energizing, verifying absence of voltage, and securing equipment before work. Study basic personal protective equipment selections for common low-voltage tasks, and understand why good housekeeping prevents trips, shorts, and accidental energization. Document everything. Start a lab journal with dates, tasks, measurements, photos of your practice boards, and short reflections on what worked and what confused you. This becomes a portfolio piece and a memory aid.

Finally, organize your study system. Use a weekly cycle:

– Two focused theory blocks (codes and fundamentals)

– Two applied sessions (practice wiring, measurement drills)

– One mixed review (flashcards, quick quizzes, and error analysis)

– One light session to plan the next week and prepare questions for instructors

With clear scheduling, refreshed math, basic tool comfort, and early safety habits, you will enter month two with momentum and lower stress.

Months 2–3: Lab Mastery, Troubleshooting Skills, and Safety Culture

By the second month, lab time becomes the engine of your progress. Anchor every session with a safety checklist: verify de-energized status, inspect cords and test leads for damage, confirm correct meter settings, and maintain a clean work area. Treat safety as a culture, not a chapter. When procedures become reflexes, you free mental bandwidth for diagnosing faults and learning advanced techniques.

Focus your lab work on repeatable builds and controlled variations. Wire basic branch circuits, single-pole and three-way switching, simple motor controls, and common receptacle configurations. After a clean install, introduce faults intentionally to practice troubleshooting: reverse polarity, open neutral, tripped overload, or miswired travelers. Record symptoms, meter readings, and final fixes. This trains you to recognize patterns quickly and builds confidence for both the exam and real job sites.

Develop a troubleshooting framework:

– Gather symptoms (what failed, when, and under what load)

– Verify power source and protection devices

– Use the meter to bracket the problem (voltage present here, absent there)

– Inspect connections and terminations systematically

– Correct the issue, retest, and document root cause

Comparisons help you choose effective methods. For example, visual inspection can catch obvious loose terminations fast, but meter-based verification eliminates guesswork when the fault is hidden. Time-and-motion tracking is useful here. Note how long each approach takes and refine your sequence. Similarly, compare solid to stranded conductors in terms of strip length, termination feel, and failure modes; your written notes will make exam questions about conductor characteristics feel familiar rather than theoretical.

Communication is another skill worth cultivating. Practice annotating diagrams and labeling your boards in a consistent, text-minimal style that avoids clutter while making the circuit logic clear. Create a small glossary in your journal for frequent terms and symbols so you can decode new schematics faster. If your program offers peer review, rotate partners each week, explain your circuit in plain language, and ask for one suggestion you can implement immediately. This habit sharpens your thinking and simulates jobsite collaboration, where clear communication reduces rework and improves safety.

Months 4–5: Codes, Calculations, and Exam Strategy

With hands-on competence sharpening, shift more attention to codes and calculations. The certification exam usually emphasizes safe installations, correct sizing, and proper use of protective devices, alongside fundamentals like Ohm’s law and power relationships. Build a structured method for each calculation type. For conductor sizing, outline steps to determine load, apply adjustment factors, consider temperature ratings, and select overcurrent protection. For voltage drop, document the formula, typical acceptable ranges for branch and feeder circuits as required in your jurisdiction, and when upsizing conductors is warranted.

Navigation skills matter as much as memorization. Create index tabs or mental maps to locate topics quickly in your reference materials, aligning to whatever rules govern your exam format. Practice by timing yourself on short look-ups so that page-flipping does not consume precious minutes during the test. Many exams set passing thresholds near the seventy percent range, though this can vary across regions. Aim for a stable practice score above that mark to create a buffer for test-day nerves.

Design a weekly exam-prep routine:

– One session focused on code navigation and quick look-ups

– One session of mixed calculations under timed conditions

– One session of conceptual review (grounding, bonding, equipment ratings)

– One session analyzing missed questions and updating your error log

Comparing study tools helps you allocate limited time. Paper practice questions can promote deeper focus with fewer distractions, while digital quizzes provide immediate feedback and randomized question pools. If you struggle with timing, choose shorter, more frequent drills to train pacing. If accuracy is your weak spot, slow down and narrate steps aloud as you solve problems, then speed up only after your error rate drops. Build a compact “formula and process” sheet that fits on a single page and rewrite it each week from memory; the act of rewriting strengthens recall.

Finally, simulate the test environment. Sit in a quiet room, follow the official time limits, and use only the allowed materials. After each mock exam, spend twice as long reviewing as you spent testing. Classify errors as knowledge gaps, reading mistakes, or pacing issues, and plan specific fixes for each category. This practical cycle turns anxiety into a checklist and makes steady improvement visible.

Month 6 and Beyond: Certification, First Job Launch, and Ongoing Growth

The last month blends review with logistics. Confirm your test date, location, identification requirements, and any rules for allowed reference materials. Prepare a simple checklist for exam day: rest, nutrition, travel time, and a brief warm-up of a few easy questions to build confidence. Keep your study load moderate during the final forty-eight hours; light repetition and short problem sets are often more effective than marathon sessions.

Meanwhile, assemble job materials that reflect your six months of work. Curate photos of lab builds, include neat diagrams, and add brief captions describing the goal, method, and result. Draft a concise resume that features safety training, hours of supervised lab work, and specific competencies such as wiring methods, measurement techniques, and troubleshooting. Practice a quick story for interviews that shows how you handled a frustrating fault, what diagnostics you used, and how you verified the final fix. Employers appreciate clarity, humility, and a habit of documenting work.

As you step into the job market, compare entry pathways. Some trainees move straight into entry-level helper roles while pursuing an apprenticeship to expand scope over time. Others focus on residential service for broad exposure to common issues, then transition to light commercial work to deepen skills with panels, feeders, and controls. Choose based on your learning goals and local opportunities, not on hype. Ask three questions before accepting a role: will I get steady supervised tasks that build core competencies, will I receive feedback on safety and workmanship, and does the schedule allow continued study toward advanced credentials.

Commit to continuous learning. Electrical systems evolve, and codes are updated on a regular cycle. Set a quarterly plan to study new sections, practice calculations you find difficult, and complete short projects that stretch your abilities. Keep your lab journal alive on the job by recording lessons learned, time-saving tricks, and safety near-misses that you turned into better habits. Over time, this living portfolio becomes both a confidence anchor and a stepping stone to new responsibilities.

Conclusion for aspiring technicians: success in a six-month course is not about shortcuts. It is the steady accumulation of safe habits, accurate calculations, clear documentation, and focused practice. If you follow the plan outlined here—prepare early, train deliberately, study codes with intention, and review your errors—you will be positioned to attempt your certification with calm focus and to step into the trade with skills that speak for you.